MIL-DTL-25308C

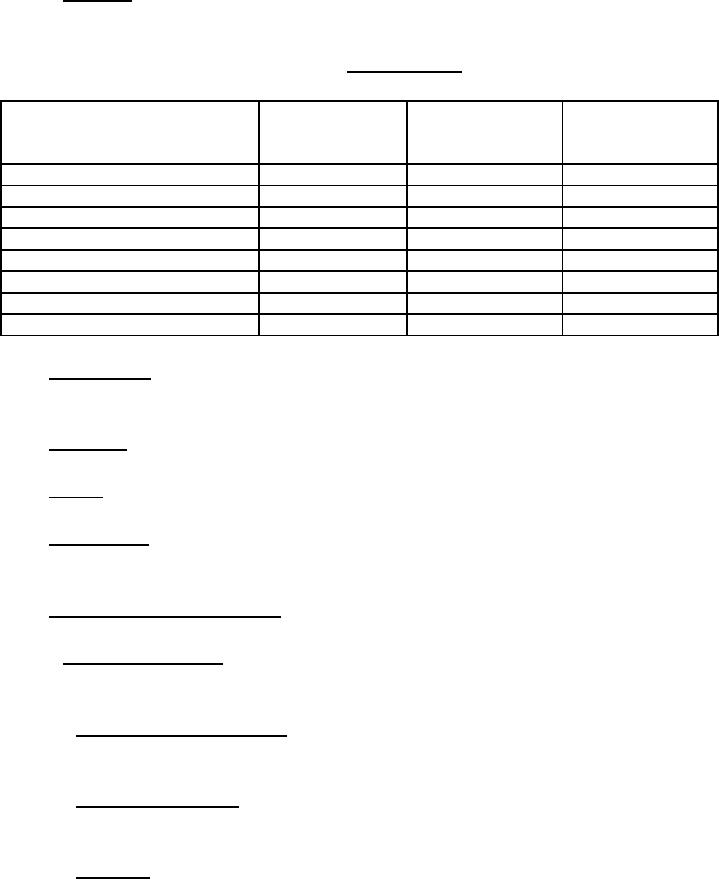

3.13.1 Markings. The markings shall be as specified in table III. Unless specified, the location

of the markings are optional.

TABLE III. Marking details.

Height or length,

Width of line or

Color

in.

Graduation, in.

Per FED-STD-595

±0.016

±0.005

Numerals, 0, 1, 2, 3, 4

0.156

0.025

37875

Major graduations

0.188

0.031

37875

Minor graduations

0.094

0.020

37875

Lettering "HYD PRESS"

0.125

0.025

37875

Lettering "PSI X 1000"

0.094

0.020

37875

Lettering :"USAF TYPE ME-1"

0.063

37038

Dial face

37038

All other markings

37038

3.14 Screw threads. Unless otherwise specified, screw threads shall be in accordance with MIL-

S-7742.

3.15 Lubricants. Lubricants shall conform to MIL-L-6085.

3.16 Weight. The weight of the gage shall not exceed 0.5 lbs.

3.17 Jewel bearing. When synthetic sapphire or ruby bearings are used, they shall conform to

MIL-B-27497.

3.18 Finishes and protective coatings.

3.18.1 Aluminum-alloy parts. Aluminum alloy parts shall be covered with an anodic film

conforming to MIL-A-8625, except as follows:

3.18.1.1 Dials, small holes and inserts. Dials, small holes, and case inserts need not be

anodized.

3.18.1.2 Non-anodizable alloys. Aluminum alloys which do not anodize satisfactorily shall be

coated with a chemical film in accordance with MIL-C-5541.

3.18.1.3 Paint base. Where the primary purpose of the treatment is to afford a suitable paint

base, chemical treatments in accordance with MIL-C-5541 may be used in lieu of anodizing.

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business