MIL-DTL-25308C

e.

Humidity relative humidity to 95 percent.

f.

Fungus fungus growth as encountered in tropical climates.

g.

Dust exposure to dry dust-laden atmosphere.

h.

Overpressure overpressure of 5,000 pounds per square inch (psi)

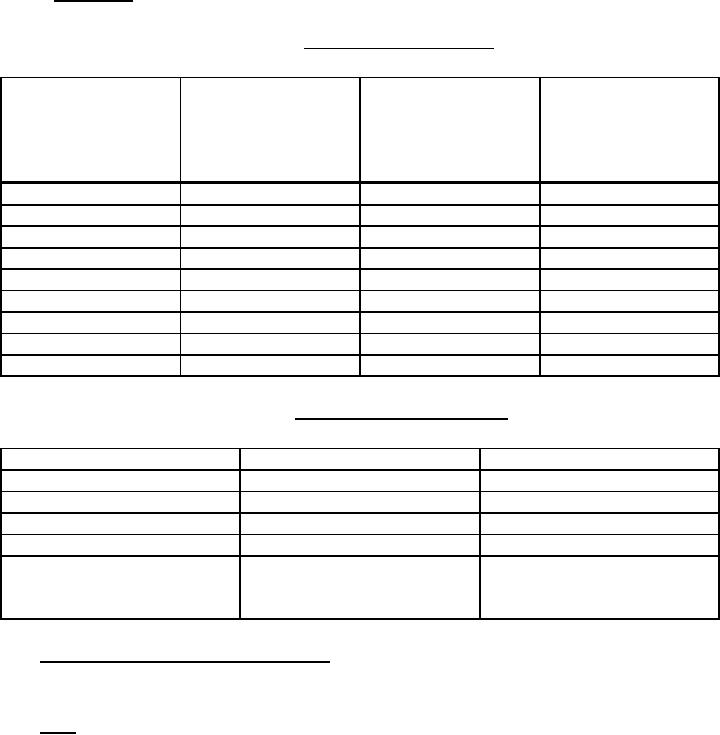

3.3.1 Tolerances. The gage shall operate within the tolerances specified in tables I and II.

TABLE I. Scale error tolerance, ąpsi.

Test Pressure (psi)

Dust

Low temp. operation

High temp. exposure

Room temp.

Low temp. exposure

Salt fog

High temp. operation

Humidity

Altitude

Vibration

0

50

75

100

500

50

100

125

1,000

50

100

125

1,500

50

100

125

2,000

50

125

150

2,500

50

125

150

3,000

50

125

150

3,500

75

125

150

4,000

75

125

150

TABLE II. Test Pressures and tolerances.

Test

Test Pressure (psi)

Tolerance (ąpsi)

Friction error all tests

----

75.0

Position error

2,000

30.0

Overpressure

5,000

80.0 + room temp tol

Seasoning

----

20.0 + room temp tol

Vibration

2,000

Pointer oscillation

100

Pointer variation

100

3.4 Part numbering of interchangeable parts. All parts having the same manufacturer's part

number shall be functionally and dimensionally interchangeable.

3.5 Case. The case shall consist of a body and a bezel ring and shall conform to figure 1. The

case body shall be made of either nonferrous, low-density metal or of a synthetic material, shall

be uniform in texture and shall have a smooth surface. The bezel and that part of the case visible

from the cockpit side of the instrument panel shall be finished in lusterless black per FED-STD-

595, color 37038. The remainder of the case may be finished in black and shall be adequately

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business