MIL-PRF-2940D

and actuate V2.

(e)

After steady state has been achieved, close V2 and relieve

the test pressure by opening V4.

(f)

As applicable, thoroughly clean the entire dampening

apparatus to remove residual traces of the fill fluid.

4.6.3

Temperature.

4.6.3.1 High temperature. Place the snubber in an environmental

chamber and pressurize the snubber to 250 + 10 psi for a class L snubber and

1500 + 50 psi for a class H snubber. Increase the chamber temperature from

ambient to 150 + 5°F in not less than 1 hour. Adjust the pressure as

necessary to maintain the required pressure. Maintain the pressure and

temperature conditions for not less than 4 hours. Reduce the chamber to

ambient temperature in not less than 1 hour. Remove the snubber from the

chamber. Allow it to remain at ambient temperature for not less than 1 hour.

The snubber shall meet the requirements of 3.4.3.

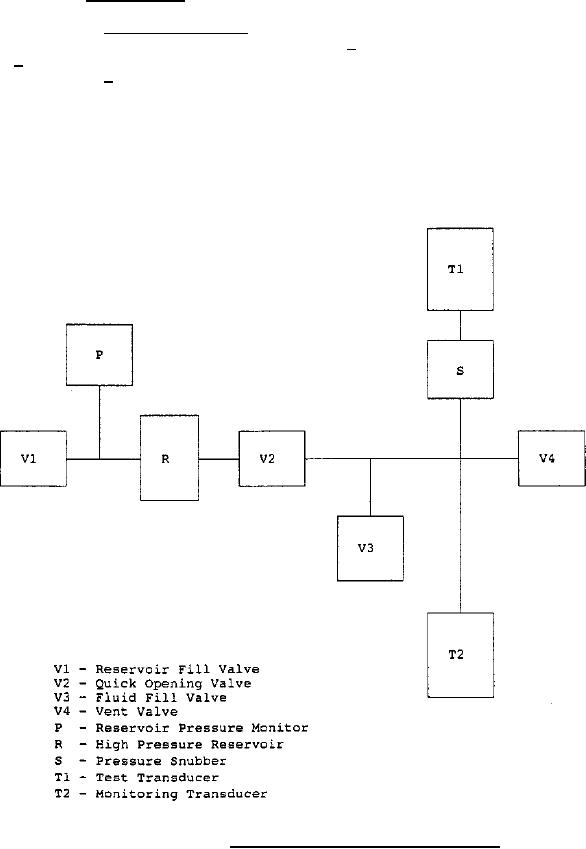

FIGURE 1.

Suggested dampening test setup.

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business