MIL-PRF-2940D

TABLE VI.

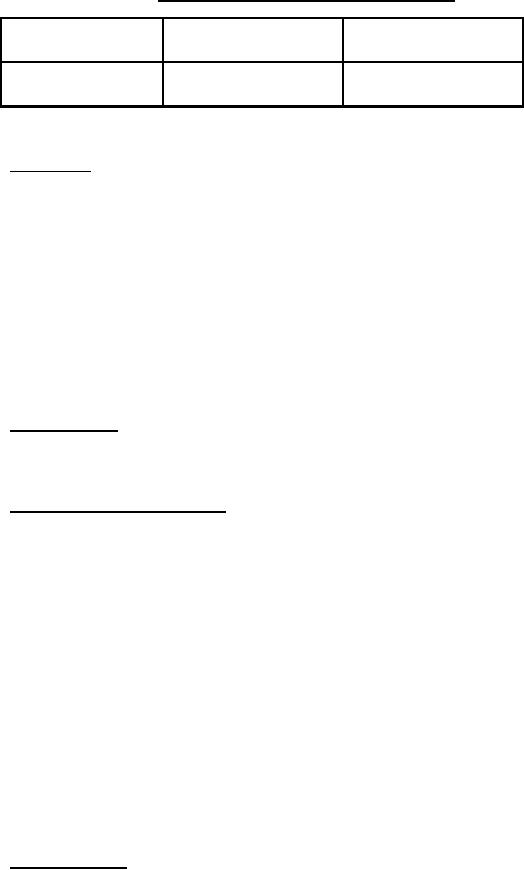

Pressure integrity test pressures.

Snubber class

Operating range

Test pressure

(see 1.2.2)

(psi)

(psi)

L

10/1000

1500

H

1001/6000

9000

5.

PACKAGING

5.1 Packaging. For acquisition purposes, the packaging requirements

shall be as specified in the contract or order (see 6.2). When actual

packaging of material is to be performed by DoD personnel, these personnel

need to contact the responsible packaging activity to ascertain requisite

packaging requirements. Packaging requirements are maintained by the

Inventory Control Point's packaging activity with the Military Department or

Defense Agency, or within the Military Department's System Command. Packaging

data retrieval is available from the managing Military Department's or Defense

Agency's automated packaging files, CD-ROM products, or by contacting the

responsible packaging activity.

6.

NOTES

(This section contains information of a general or explanatory nature

that may be helpful, but is not mandatory.)

6.1 Intended use. Snubbers are intended for use in pressure instrument

piping systems to suppress pressure spikes and dampen pressure fluctuations

(both periodic and nonperiodic) before they can reach and damage pressure

sensing instrumentation.

6.2 Acquisition requirements.

Acquisition documents should specify the

following:

(a)

Title, number and date of this specification.

(b)

Snubber classification variables, as follows:

(1)

Type of service (see 1.2.1).

(2)

Class (see 1.2.2).

(3)

Material composition, excluded, selected by

manufacturer (see 1.2.3 and 3.2).

(4)

End connection (see 1.2.4).

(5)

Cleanliness (see 1.2.5).

(c)

Issue of DoDISS to be cited in the individual documents

referenced (see 2.2.1).

(d)

When first article is required (see 3.1).

(e)

If union nut, tail piece, and O-ring should be furnished with

each snubber that is intended for pressure gauge general

applications (see 3.3.2.1.1).

(f)

Special cleaning (see 3.3.3).

(g)

Packaging requirements (see 5.1).

6.3 First article. When first article inspection is required, the con-

tracting officer should provide specific guidance to offerors whether the

item(s) should be a preproduction sample, a first article sample, a first

production item, a sample selected from the first production items, a standard

production item from the contractor's current inventory, and the number of

items to be tested as specified in 4.2. The contracting officer should also

12

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business