MIL-PRF-2940D

3.4.6 Pressure integrity. The snubber under test shall withstand the

pressure specified in 4.6.6 without showing any evidence of leakage or damage.

Upon completion of the pressure integrity test, the snubber under test shall

meet the dampening requirement of 3.4.2.

3.5 Cleaning and surface finishes. Surfaces of castings, forgings,

molded parts, stampings, machined, and welded parts shall be free of defects

such as cracks, porosity, undercuts, voids, and gaps as well as sand, dirt,

fins, sharp edges, scale, flux, and other harmful or extraneous materials.

External surfaces shall be smooth and edges shall be either rounded or

beveled. There shall be no burn-through. There shall be no warpage or

dimensional change due to heat from welding operations. There shall be no

damage to adjacent parts resulting from the welding.

4.

VERIFICATION

4.1 Classification of inspections. The inspection requirements

specified herein are classified as follows:

(a)

First article inspection (see 4.2).

(b)

Conformance inspection (see 4.3).

4.2 First article inspection. First article inspection shall be

performed and passed prior to production and shall be witnessed by a

Government inspector. First article inspection shall be performed on samples

which have been produced with equipment and procedures normally used in

production. First article inspection shall consist of the examination and

tests specified in table I and in the sequence listed.

4.2.1 Sample size. Two snubber samples of each type, class,

composition, and end connection shall be subjected to the first article

inspection.

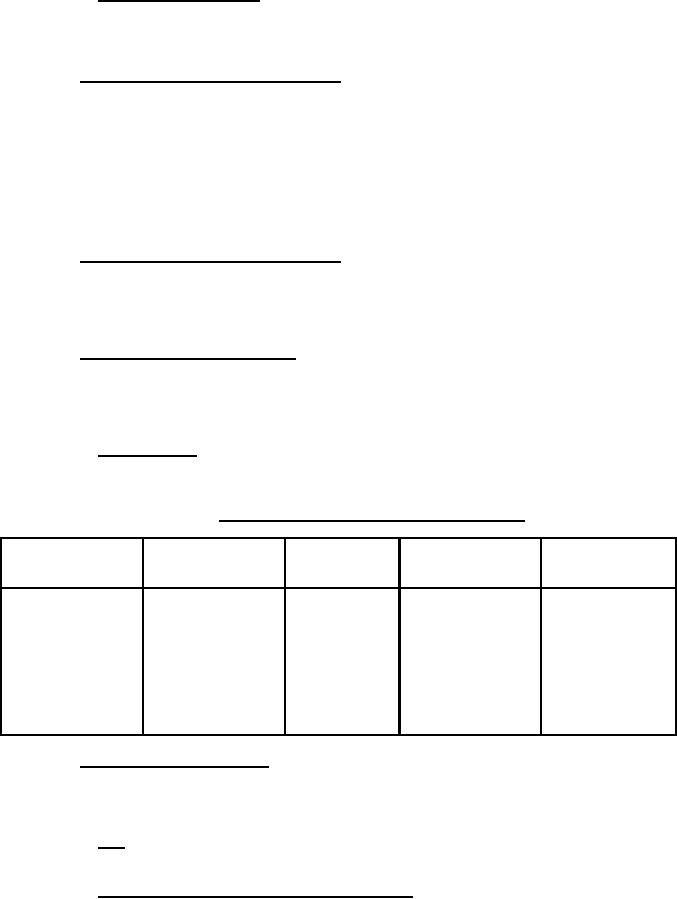

TABLE I.

Inspection, examination, and tests.

Test

First article

Conformance

Inspection

Requirement

procedures

inspection

inspection

Examination

3.2, 3.3, 3.5

4.5

X

X

Steady state

3.4.1

4.6.1

X

-

transmission

Dampening

3.4.2

4.6.2

X

X

Temperature

3.4.3

4.6.3

X

-

Vibration

3.4.4

4.6.4

X

-

Shock

3.4.5

4.6.5

X

-

Pressure

3.4.6

4.6.6

X

X

integrity

4.3 Conformance inspection. Conformance inspection shall be performed at

the place of manufacture. Conformance inspection shall consist of the

examination and tests specified in table I and shall be witnessed by a

Government inspector.

4.3.1 Lot. A lot shall consist of all snubbers of the same type,

class, composition, and end connection manufactured at one time.

4.3.2 Sampling

for conformance inspection. A random sample of snubbers

will be selected by a

Government inspector from each lot of snubbers (see

4.3.1 for conformance

inspection (see 6.4). Sample size shall be in

accordance with table

II.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business