MIL-PRF-2940D

TABLE II.

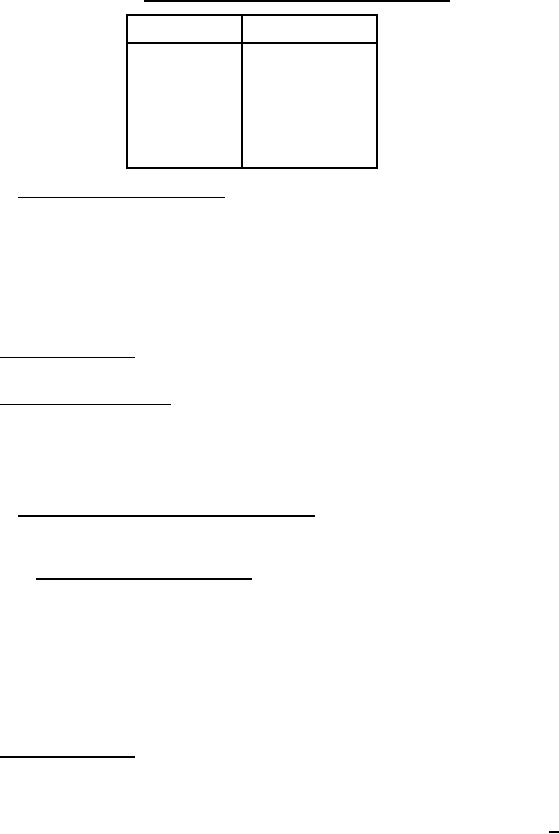

Conformance inspection sample size.

Lot size

Sample size

1

-

8

4

9

-

15

7

16

-

25

12

26

-

90

19

91

-

150

25

151

-

280

38

281

-

500

60

4.3.3 Lot acceptance criteria. If any snubber sample fails to meet the

conformance inspection requirements of table I, no snubbers will be accepted

until the contractor has determined the cause of the defect and has taken the

necessary action to correct or eliminate the defect from each snubber in the

lot. The failed test must be repeated to demonstrate that the corrective

action will enable the snubber to conform to the requirements of the

specification. In addition, the results of previous tests may be deemed

invalid, unless the contractor can prove to the satisfaction of the Government

that such tests would not be adversely impacted by the corrective action.

4.4 Test conditions. Test conditions shall be as specified in the

applicable examinations and test procedures.

4.5 General examination. The snubbers shall be subjected to a thorough

examination to ascertain that the material, finish, workmanship, construction,

assembly, dimensions, and marking are in conformance with the requirements of

this specification. Examinations shall be limited to disassembling the

snubbers to the extent that the performance, durability, or appearance would

not be affected.

4.5.1 Conformance inspection examination. The snubbers selected as

specified in 4.3.2 shall be examined to determine conformance to the

requirements of this specification.

4.5.1.1 Dimensional verification. Snubber samples selected as

specified in 4.3.2 shall be subjected to dimensional verification of the

pressure connection threaded end to verify conformance to the applicable

document for the type threaded end or connection specified (see 6.). In order

to comply with the dimensional verification, all dimensions, concentricities,

and perpendicularities affecting interchange- ability of parts, sealing

effectiveness, strength and body size (see 3.3.1), shall be measured with

sufficient precision to verify conformance to the applicable document. For a

snubber having an O-ring union pressure connection, samples of the tail piece

and a union nut shall also be subjected to this dimensional verification.

4.6 Test procedures. Tests shall be conducted as described below. For

the dampening test, a storage oscilloscope, oscillographic recorder, or other

data acquisition system with a frequency response sufficient to resolve full

scale deflections in 10 milliseconds or less shall be utilized. Input signal

resolution shall be 2 percent or less of full scale. Signals from both the

test and monitoring transducers shall be recorded simultaneously (see 4.56.2).

With the exception of the dampening test, which requires the use of pressure

transducers, all other tests may be monitored with either a pressure

transducer or a pressure gauge of suitable range which shall have accuracies

of 1 percent of span or better and shall have an overpressure rating of at

least 125 percent of upper range value. To maintain sufficient accuracy, the

maximum upper range limit for any pressure transducer or pressure gauge shall

not exceed twice the maximum pressure expected in any test. In addition,

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business