MIL-PRF-2940D

4.6.3.2 Low temperature. Place the snubber in an environmental chamber

and pressurize the snubber to 250 + 10 psi for a class L snubber and 1500 + 50

psi for a class H snubber. Decrease the chamber temperature from ambient to

40 + 5°F in not less than 1 hour. Adjust the pressure as necessary to

maintain the required pressure. Maintain the pressure and temperature

conditions for not less than 4 hours. Increase the chamber to ambient

temperature in not less than 1 hour. Remove the snubber from the chamber and

allow it to remain at ambient temperature for not less than 1 hour. The

snubber shall meet the requirements of 3.4.3.

4.6.3.3 Temperature cycling. Place the snubber in an environmental

chamber. The snubber shall remain unpressurized during the temperature

cycling. The test shall consist of 4 complete cycles (steps 1 through 4), as

shown in table IV. After completion of the 4th cycle, the snubber shall be

removed from the chamber and allowed to stabilize at ambient conditions for

not less than 1 hour. The snubber shall meet the requirements of 3.4.3.

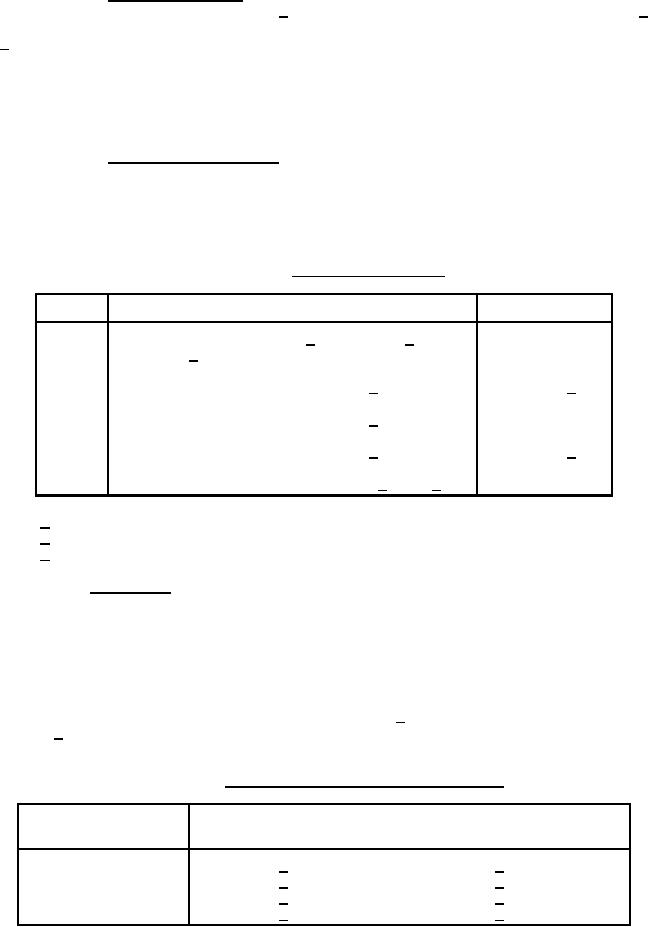

TABLE IV.

Temperature cycle.

Step

Temperature condition

Duration

1

Increase temperature 1/ from 75 + 5°F

1 hour

to 150 + 5°F

2

Constant temperature of 150 + 5°F

22 hours 3/

3

Decrease temperature to -10 + 5°F

2 hours

4

Constant temperature of -10 + 5°F

22 hours 3/

5

Increasing temperature to 75 + 5°F 2/

1 hour

1/ Ambient temperature for the first cycle.

2/ Ambient temperature for the last cycle.

3/ Minimum duration.

4.6.4 Vibration. The snubber shall be tested in accordance with type I

(environmental) vibration of MIL-STD-167-1 except that the upper frequency

shall be 175 hertz (Hz); the amplitude of vibration shall be as specified in

table V; and for the variable frequency portion, the vibration level shall be

maintained for 2 minutes at every integral value of frequency. If no

resonances are observed, the 2-hour endurance test shall be conducted at 175

Hz. If a particular snubber is determined to be axisymetric, then the

vibration test need only be conducted along the two mutually perpendicular

axes. The snubber shall be pressurized to 250 + 10 psi for a class L snubber

and 1500 + 50 psi for a class H snubber and monitored throughout the test.

The snubber shall meet the requirements of 3.4.4.

TABLE V.

Vibratory displacement criteria.

Frequency range

Table displacement (inches peak to peak)

(Hz)

Exploratory Variable frequency

5

to

20

0.020

+

0.004

0.060

+

0.012

21

to

50

0.010

+

0.002

0.040

+

0.008

51

to

100

0.003

+

0.0006

0.020

+

0.004

101

to

175

0.001

+

0.0002

0.003

+

0.0006

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business