MIL-PRF-2940D

controls of the storage oscilloscope, oscillographic recorder, or other data

acquisition system should be set that recorded signals are at least 50 percent

of full scale. Except for the dampening tests which require a specific fill

fluid, the others may employ fresh water as the fill fluid. If fresh water is

used as the fill fluid for the temperature test, provision should be made to

employ a suitable additive to prevent freezing. As applicable, the snubber

should be thoroughly cleaned prior to conducting the dampening test. The fill

fluids for the dampening test shall be as follows:

(a)

Type 1: 2190-TEP oil in accordance with MIL-PRF-17331

an equivalent oil may be substituted).

(b)

Types 2 and 4: Fresh water.

(c)

Type 3: Air or nitrogen.

Unless otherwise indicated, the pressure transducer or pressure gauge shall be

connected to the output side of the snubber with only an adapter fitting

between them. Except where temperature is a variable, the tests in this

specification shall be conducted at an ambient temperature of 75 + 10°F.

4.6.1 Steady state transmission. A reference measurement shall be made

employing either a pressure transducer or pressure gauge, both with and

without a snubber. The reference measurement shall be made both upscale and

down scale at the test pressures for the applicable class (see 1.2) as shown

in table III. The snubber shall meet the requirements of 3.4.1.

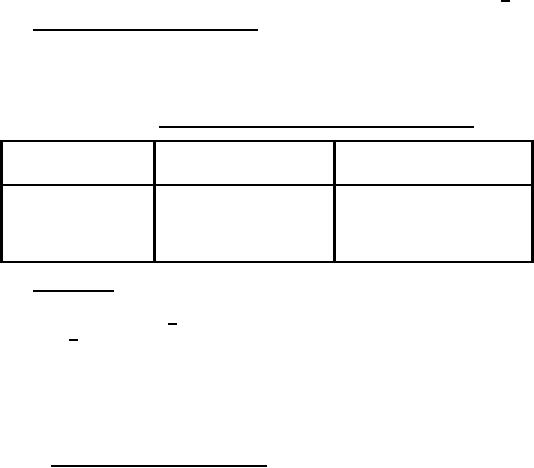

TABLE III.

Steady state transmission pressures.

Snubber class

Operating range

Test pressures

(see 1.2.2)

(psi)

(psi)

L

10/1000

10, 250, 500, 750,

1000

H

1001/6000

1200, 2400, 3600,

4800, 6000

4.6.2 Dampening. The dampening test shall be conducted utilizing an

apparatus similar to that shown on figure 1. A step change shall be made from

atmospheric pressure to 200 + 10 psi for class L snubbers and from atmospheric

pressure to 1500 + 100 psi for class H snubbers. The pressure step change

shall be accomplished in 100 milliseconds or less as measured with the

monitoring pressure transducer. Both the test and monitoring pressure

transducers shall have frequency response characteristics sufficient to

respond to and produce an electrical signal output in response to a full scale

pressure change occurring in 10 milliseconds or less. The snubber shall meet

the requirements of 3.4.2.

4.6.2.1 Dampening test procedure. The following procedure, applicable

to figure 1, may be used to perform the dampening test:

(a)

Ensure that V2 and V4 are closed and that V3 is open.

(b)

Utilizing V3, introduce the fill fluid, as applicable into

the monitoring and test transducer legs. Loosen the

fittings at T1 and T2 to ensure a complete fill. Tighten

all transducer fittings and close V3 after the fill

procedure is complete.

(c)

Utilizing V1, pressurize the high pressure reservoir with

nitrogen to a value sufficient to ensure that the pressure

step change in the transducer legs will satisfy the criteria

of 4.6.2. Close V1.

(d)

Energize the transducers and applicable monitoring equipment,

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business