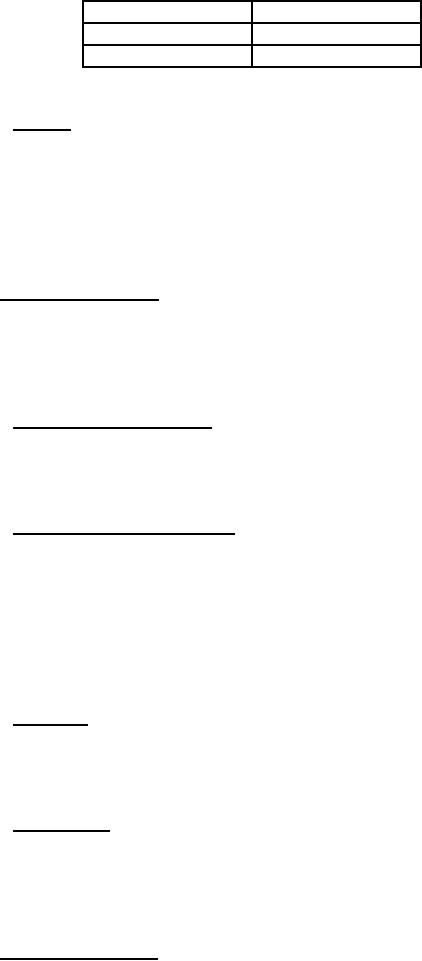

MIL-DTL-6019E

400*

25

450

25

500

25

*Test points.

4.4.1.4 Friction. The gage shall be tested for friction at all points indicated by an asterisk

in table III, beginning with the second asterisk point, and the specified tolerances shall not be

exceeded. The pressure shall be increased in order to bring the pointer approximately to the

desired reading and then held constant while two readings are taken, the first before the gage is

tapped, and the second after the gage is tapped. The pointer shall move smoothly while the

pressure is varied uniformly without vibration of the gage. This test may be combined with the

test for scale error at room temperature.

4.4.2 Sampling plan A tests. Sampling plan A tests are in addition to the individual tests

and shall include the tests specified in 4.4.2.1 through 4.4.2.4. Unless otherwise specified (see 6.2),

the manufacturer, in accordance with MIL-STD-1916, shall select the type of sampling plan

(attribute, variable, or continuous). The sample size shall be selected in accordance with

verification level I of MIL-STD-1916.

4.4.2.1 High temperature operation. The gages shall be subjected to a temperature of 160 ºF

for a period of 3 hours. The gages shall be subjected to the individual tests specified in 4.4.1, while

at the high temperature. The readings observed for the scale error at room temperature and friction

tests shall not differ from the individual test readings by more than ±25 psi.

4.4.2.2 Vibration and low temperature. The gages shall be subjected to a temperature of

-65 ºF and subjected to vibration for a period of 3 hours on a suitably designed vibration stand,

duplicating as nearly as practicable an actual installation. The vibration shall be in any plane

with respect to the instrument with a double amplitude of from 0.018 to 0.020 inch and frequency

of 500 to 2,500 cpm. After the 3-hour period of vibration, and while the gages are still being

vibrated at the specified temperature, they shall be tested for scale errors as described in the scale

error at room temperature test specified in 4.4.1.3. The readings shall not differ from the

individual test readings by more than ±25 psi.

4.4.2.3 Seasoning. The gage shall be subjected to 300 applications of pressure from 0 to

500 psi. Not less than 1 hour later, the gage shall be tested for scale error and friction as

specified in 4.4.1.3 and 4.4.1.4. The readings obtained after the applications of the differential

pressure shall not differ from those obtained in the individual tests by more than ±10 psi.

4.4.2.4 Overpressure. The gage shall be subjected to a pressure of at least 1,000 psi for a

period of 10 minutes. Not less than 1 hour after the release of the overpressure, the gage shall be

subjected to the individual tests specified in 4.4.1. The readings obtained in the scale error at

room temperature and friction tests shall not differ from those obtained in the original individual

tests by more than ±25 psi.

4.4.3 Sampling plan B tests. Sampling plan B tests are in addition to the individual and

sampling plan A tests and shall include the tests specified in 4.4.3.1 through 4.4.3.6. Unless

15

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business