MIL-DTL-6019E

4.2.3 Tapping. Unless otherwise specified, the instrument shall be tested in normal vertical

operating position and shall be lightly tapped before a test reading is taken.

4.2.4 Vibration. Whenever vibration is specified, it shall be at any desired frequency

between 300 and 3,000 cpm and at a double amplitude of 0.018 to 0.020 inch.

4.3 First article inspection. When a first article inspection is required, it shall undergo all of

the tests specified in 4.4. The presence of any defect shall be cause for rejection of the first article.

4.4 Conformance inspection. Conformance inspection shall be in accordance with

MIL-STD-1916 and shall consist of individual tests (see 4.4.1) for each gage produced, as well as

sampling plan A tests (see 4.4.2) or sampling plan B tests (see 4.4.3) as specified (see 6.2).

4.4.1 Individual tests. Each gage shall be subjected to the following tests.

4.4.1.1 Examination of product. Each gage shall be examined to determine conformance

with this specification with respect to materials, design, construction, and workmanship.

4.4.1.2 Leaks. Following completion of all the sampling tests, the gage shall be subjected

to a pressure of at least 500 psi. This pressure shall be locked in the gage and the supply

disconnected as close to the gage as practicable. The hand shall then be observed for deviation

from the original pressure setting. Any drop of pressure that can be attributed to leaks in the gage

will be cause for rejection.

4.4.1.3 Scale error at room temperature. The gage shall be tested for scale error at the

points on the scale indicated by an asterisk in table III, and shall not exceed the corresponding

tolerances. Tests shall be made by subjecting the gage to the pressures required to produce these

readings, first with pressures increasing, then with pressures decreasing. With the pressures

increasing, the pressure shall be brought up to, but shall not exceed, the pressures required to give

the desired readings. With the pressures decreasing, the pressure shall be brought down to, but shall

not fall below, the pressure required to give the desired readings. At the discretion of the procuring

activity, gages may be tested for scale error at any additional point or points on the scale.

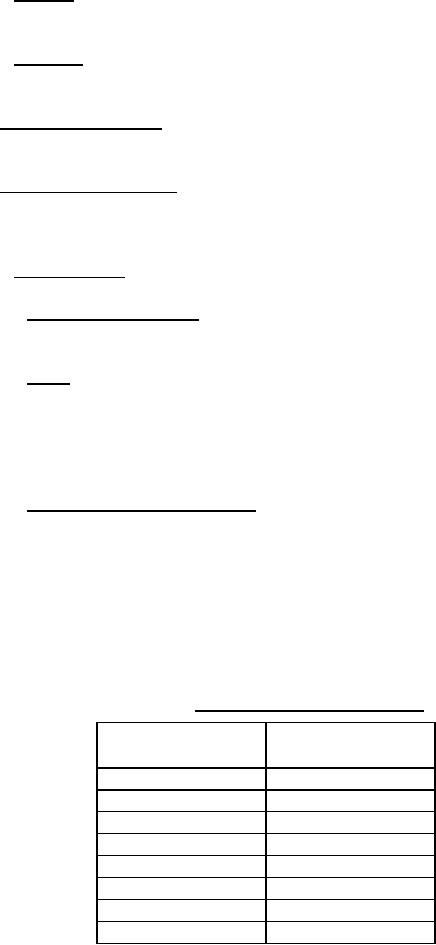

TABLE III. Scale error at room temperature.

Test pressure

Tolerance (±)

(psi)

(psi)

0*

10

50

10

100*

15

150

15

200*

25

250

25

300*

25

350

25

14

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business