MIL-DTL-27190C

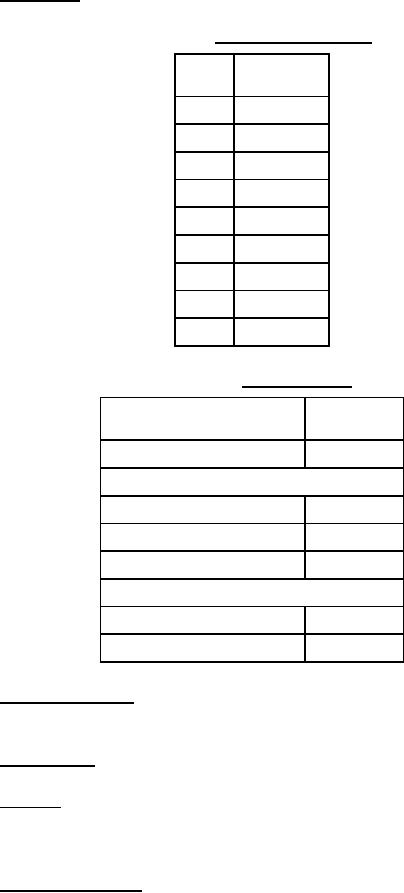

3.4.1 Tolerances. The indicator shall operate within the tolerances specified in tables II and III.

TABLE II. Scale error tolerances.

Tolerance

PSI

ąpsi

0

50

500

50

1,000

50

1,500

50

2,000

50

2,500

50

3,000

50

3,500

50

4,000

50

TABLE III. Test tolerances.

Tolerance

Test

ąpsi

Position error at 2,500 psi

25

Friction:

Room temperature

50

High temperature

50

Low temperature

75

Vibration:

Pointer oscillation

50

Pointer variation

50

3.4.2 Dielectric strength. The indicator shall withstand 200V root square mean (rms) at

a commercial frequency for a period of 5 seconds.

3.4.3 Case leakage. Case leakage shall not exceed 0.1 micron cubic foot per hour.

3.4.4 Fogging. There shall be no evidence of moisture or oil fogging of the cover glass

when the indicator is subjected to a temperature of 85 °C ą 5 °C for a minimum period of 2 hours

and then the face of the cover glass is immediately immersed in an ice bath for 3 minutes.

3.4.5 Step input response. The time required for the indicator to properly respond to a

step input equivalent to a 2,000-psi pressure change shall not exceed 2.0 seconds with not more

than two overshoots.

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business