MIL-DTL-27190C

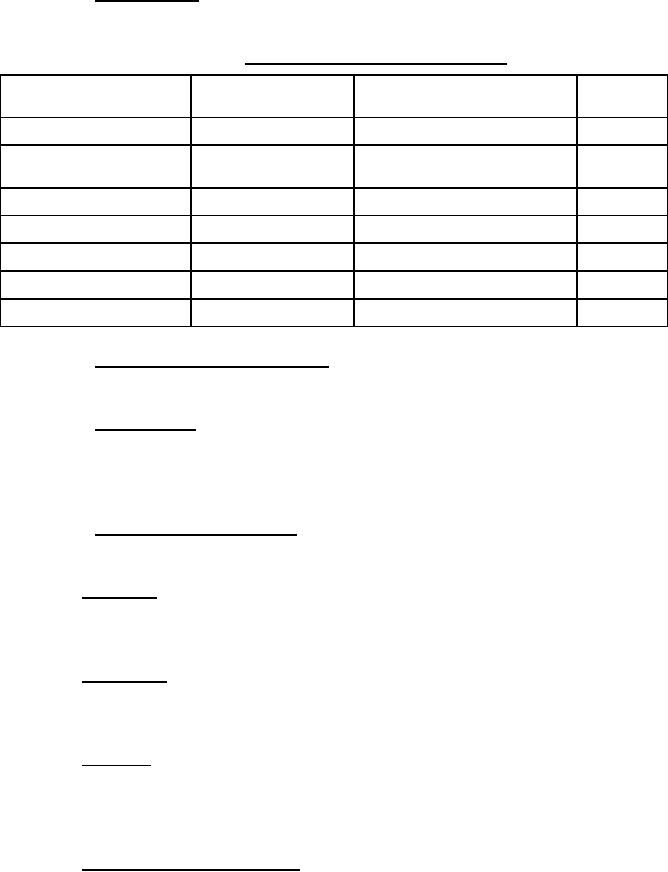

3.3.4.1 Dial markings. The dimensions and colors of the dial markings shall be in

accordance with table I. Colors shall conform to FED-STD-595.

TABLE I. Dial marking dimensions and colors.

Height or length

Width of line or graduation

Color

in inches ±1/64 inch

in inches ±0.005 inch

number

Numerals 0, 1, 2, 3, 4

3/32

0.0213

37875

Graduations at 0, 1,000,

7/64

0.030

37875

3,000, 4,000

Graduation at 2,000

3/32

0.030

37875

500-psi graduations

1/16

0.015

37875

Lettering "HYD"

5/64

0.015

37875

Lettering "X1000"

5/64

0.010

37875

Background of dial

--

--

37038

3.3.4.2 Finish of markings not specified. The finish of markings not otherwise specified

shall be in accordance with FED-STD-595, color number 37038.

3.3.4.3 Dial visibility. Portions of the minor graduations on the dial shall be visible

when viewed from any position within the frustum of a cone, the side of which intersects the

outer edge of the cover glass and makes an angle of 30 degrees with the perpendicular through

the center of the dial.

3.3.4.4 Dial-to-cover glass distance. The distance between the indicator dial and the

inside of the cover glass shall be the minimum practicable and shall not exceed 0.188 inch.

3.3.5 Filler tube. A tube or other facility for evacuating and filling the case shall be

provided at the rear of the case and shall be recessed beneath the level of the back plate surface.

If a tube is used, it shall be of such length as to permit three refillings of the case.

3.3.6 Cover glass. The cover glass shall be clear, flat, and free from flaws that would

interfere with the normal reading of the instrument. The thickness of the cover glass shall be the

minimum practicable and suitable for the purpose.

3.3.7 Fasteners. The dial shall be securely fastened to the frame of the mechanism in

such a manner that it will not loosen or turn when the indicator is vibrated. If screws are used

for attaching the dial, they shall be located so that they will not interfere with dial markings or

prevent the markings from being located in the proper position.

3.3.8 Electrical zero reference mark. The dial shall be provided with an electrical zero

reference mark on the scale portion equidistant in angular degrees between the first and last dial

graduations.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business